- Preparation, Performance and Slag Resistant Mechanism of Low Thermal Conductivity Microporous Corundum

- 作者:FU Lyuping*,HUANG Ao,GU Huazhi, ZHANG Meijie, LI Zhengkun, ZHAO Yi

- 作者机构:The State Key Laboratory of Refractories and Metallurgy, Wuhan University of Science and Technology

- 分类号:

- 卷号:24

- 期号 : 2015 年, 第4期

- 页码:23 - 30

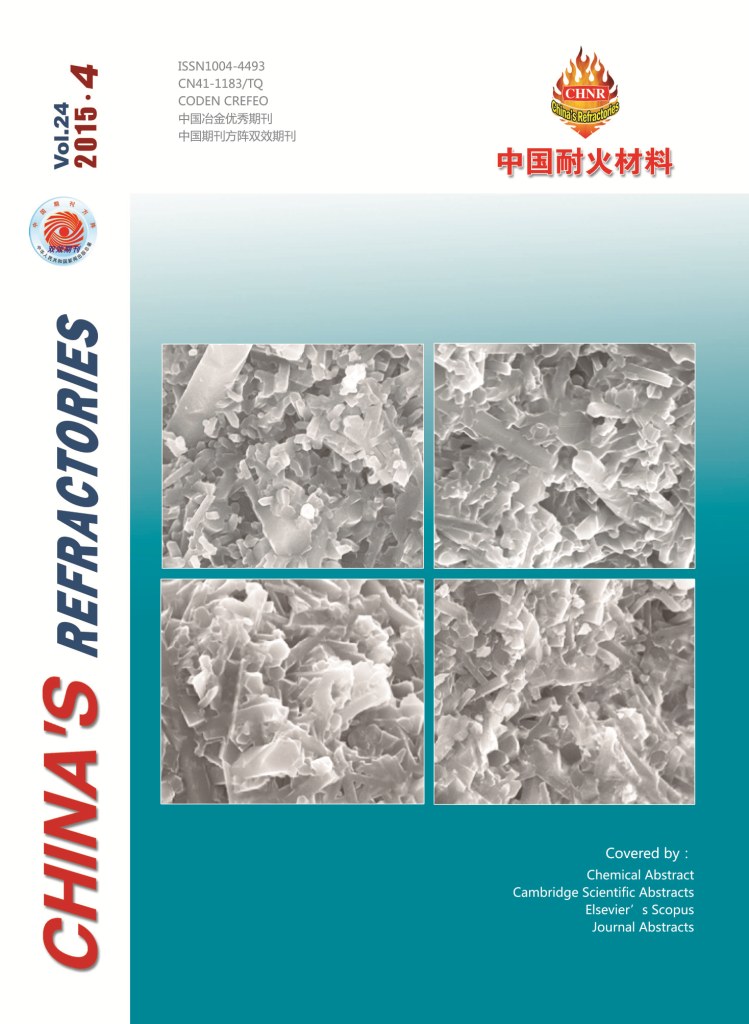

The microporous corundum material was prepared using alumina micro-powder as the main raw material, alumina sol and starch as binders by a wet process, achieving the bulk density of 3.05 g·cm-3, the apparent porosity of 9.1%, the closed porosity of 12.3%, the median pore diameter of 0.43 μm, and the thermal conductivity of 6.5 W·m-1·K-1 at 800 ℃ which is 41.6% lower than that of common corundum. The slag resistance of the microporous corundum material was studied by immersion and compared with that of the common corundum aggregate, and the slag resistant mechanism of microporous corundum material was revealed. The results show that the slag resistance of the microporous corundum material is superior to that of the common corundum aggregate, the SEM and EDX show that on the reaction interface between microporous corundum and molten slag, a continuous isolation layer with a large quantity of CA2 and CA6 columnar crystals is formed; while the common corundum aggregate reacts with the molten slag interface to form a discontinuous isolation layer of columnar crystals, through which a lot of molten slag corrodes or permeates into the aggregate. The mechanism is mainly that the microporous structure is more advantageous to nucleation and growth of CA2 and CA6 columnar crystals; in the reaction with the aggregate, the molten slag gets saturated and the critical solution thickness of the microporous corundum and the common corundum is 0.16 μm and 0.34 μm, respectively, this is caused by the smaller microporous corundum aggregate pores; and the smaller pores also increase the second phase ripening rate of microporous corundum, which is 9.7 times of that of the common corundum.

- Effect of Pelletized Graphite Addition [194]

- Optimization and Application of Corund [233]

- High Alumina Fiber Composite SiO2 Base [259]

- Effect of Al2O3-ZrO2 Composite Powder [318]

- Preparation, Performance and Slag Resi [246]

- Preparation and Properties of Alumina [370]

- Preparation of Porous Ceramic Bond cBN [283]