- Carbonization of Ni-doped Phenol Resin Under Various Conditions

- 作者:WEI Guoping, ZHU Boquan, LI Xiangcheng, MA Zheng

- 作者机构:Zhejiang Zili Co., Ltd.

- 分类号:

- 卷号:26

- 期号 : 2017 年, 第2期

- 页码:25 - 30

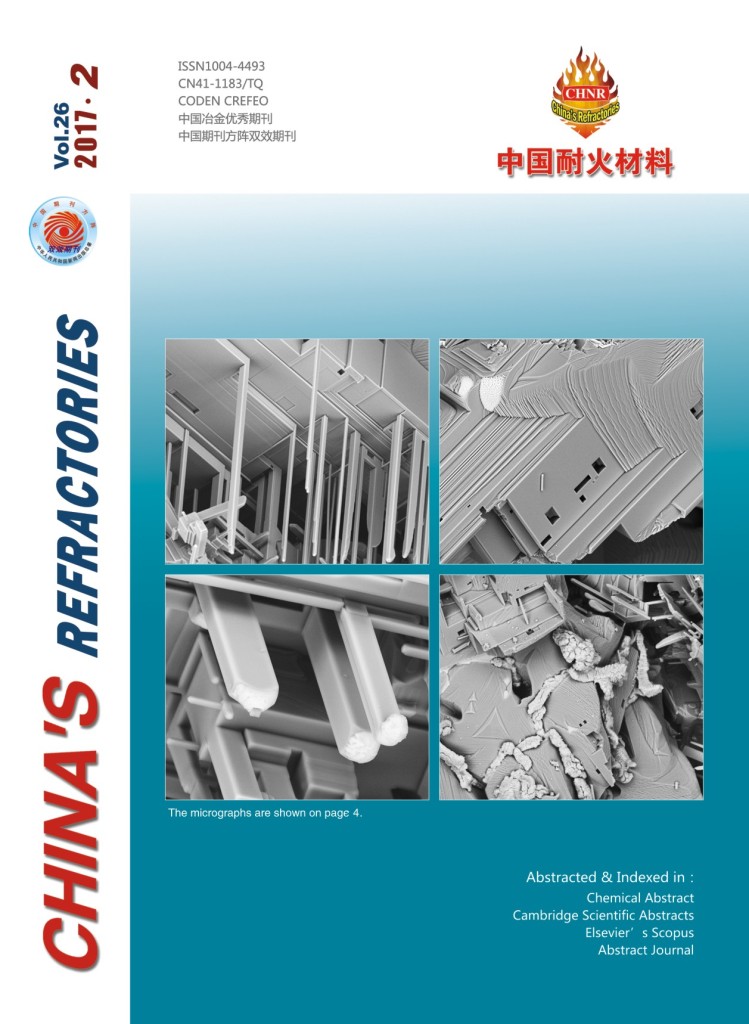

Ni-doped phenol resin was prepared with 1∶100 mass ratio of Ni(NO3)2·6H2O to thermosetting phenol resin to optimize the structure and properties of pyrolytic carbon derived from phenol resin and increase its carbon yield. The specimens were cured at 200 ℃ and carbonized under different atmospheres (carbon-embedded atmosphere and Ar atmosphere) and at different temperatures ( 600, 800, 1 000 and 1 200 ℃) for 3 h, respectively. The carbon yield was measured. Thermal decomposition characteristics of Ni-doped phenol resin, and the oxidation resistance, phase composition and microstructure of pyrolytic carbon were characterized by differential scanning calorimetry, X-ray diffraction, energy dispersive spectroscopy, scanning electron microscopy and transmission electron microscopy. The results show that the carbon yield of Ni+doped phenol resin carbonized at 800 or 1 000 ℃ is increased significantly, compared with that without any dopants. The graphitization degree of pyrolytic carbon structure derived from Ni-doped phenol resin increases with the increase of carbonization temperature. The massive multi-wall carbon nanotubes of 50-100 nm in diameter and of micrometre scale in length are generated at 1 000 ℃. Compared with the carbon-embedded atmosphere, carbon nanotubes can be more easily generated in Ar atmosphere, resulting in higher –carbon- yield and degree of crystallinity of the pyrolytic carbon derived from Ni-doped phenol resin. The oxidation resistance of the pyrolytic carbon derived from Ni-doped phenol resin at 1 200 ℃ is improved significantly and its highest oxidation temperature is increased by about 84 ℃, compared with that from Ni free phenol resin.

- Effect of Andalusite on Properties of [563]

- Influence of Kyanite Content on Micros [411]

- Carbon Containing Lining Applied on 12 [392]

- Main Influencing Factors on Service Li [431]

- Carbonization of Ni-doped Phenol Resin [416]

- Analysis on Abnormity Erosion of Monol [612]

- Research and Application of Wear Resis [641]